As the automotive, industrial, and powdered metal industries have changed so has Clarion Sintered Metals. Tighter dimensional control, increased cleanliness requirements, unique design challenges, or value-added operations: Clarion Sintered Metals has kept pace with our customer’s ever-changing needs through innovation and continuous improvement.

Engineering

Our Engineering staff is working continually to improve processes, develop robust part designs, and implement cost-effective manufacturing solutions for our customers. Whether you need a single-level spacer, complex power steering hubs, PTFE seals or washers, grooved drive pulleys, or multi-component subassemblies, Clarion Sintered Metals will assist you from your initial design concept all the way through the product’s life cycle.

We offer:

- Engineering assistance for robust part designs to improve component integrity

- Near-net shape designs to minimize or eliminate costly secondary machining operations

- Process options to achieve dimensional requirements and statistical capability

- Material recommendations and formulations to optimize part performance and part design

Quality

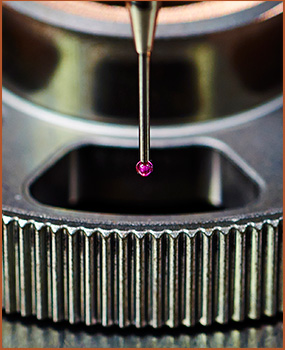

As the complexity of today’s powdered metal components and part designs have evolved so have the requirements for greater dimensional control. Clarion Sintered Metals has made significant investment in new systems and technologies to stay on the leading edge of what is possible in the world of measurement. This allows us to measure our components with the highest levels of accuracy and precision. Our Quality lab is equipped with the latest equipment including:

- Laser Measurement Systems

- CMM Scanning Measurement

- 3-D measurement system

- Contour tracer

Metallurgical Testing Lab

To assure that our products and materials meet the physical and chemical properties required by our customers, CSM’s Materials Testing Lab is furnished with a full complement of analytical equipment and staffed by trained technicians. Some of the tests we can provide include:

- Chemical testing

- Microstructure Analysis

- Microhardness

- Carbon Analysis

Tooling

Our in-house tool shop is fully equipped to build your mass production tooling from start to finish, as well as perform any required maintenance and repairs. This assures our customers of the lowest costs and shortest leadtimes for their tooling.

We also have technical agreements with select local tooling sources, if necessary.