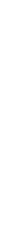

In order to support planned growth and customer needs, Clarion Sintered Metals continues to reinvest in new equipment, processes, and technologies. This assures our customers adequate capacity, robust PM manufacturing processes, and advances in technology not seen elsewhere in the industry. Our “powder-to-box” methodology replaces the conventional “batch-and-queue” approach to PM manufacturing, thereby reducing costs and lead time, and improving quality, efficiency, and throughput.

Equipment Highlights

Auto-Lines

- 21 active

Compacting

- Mechanical and hydraulic presses with tonnage range from 20 – 400 tons

Sintering

- Conventional and high temperature sintering, sinter hardening

- On-site nitrogen generation facility for furnace atmosphere

Steam Treatment

- Continuous feed steam treat systems

Secondary Processes

- Assembly

- PTFE Banding

- CNC Machining

- Tapping

- Deburring

- Oil Dip

Outside Secondary Operations

- Plating

- Heat treatment

- Grinding

- Impregnation (oil and resin)

- Tumbling